Mechanical performance of 2D tilings as a function of

geometry and material properties

The tiling of surfaces with repeated geometric elements is a common structural motif in biological tissues. Those tilings exist at a variety of size scales: from the micron-scale plates in the layers of nacre in mollusc shells, to the sub-millimeter mineralized tiles (tesserae) sheathing the cartilages of sharks and rays (Seidel et al., 2016), to the macroscopic plates in the body armors of boxfish and turtle shells. The shapes and materials of the tiling subunits, their spatial arrangement, and their physical interactions control composite functional properties, guiding deformation and hindering damage propagation. We used two-dimensional analytical models to evaluate the mechanical performance of stingray skeleton-inspired tessellations, as a function of their material and structural parameters (

Jayasankar et al. 2017. Mechanical behavior of idealized, stingray-skeleton-inspired tiled composites as a function of geometry and material properties. Journal of the mechanical behavior of biomedical materials, 73, 86-101 ).

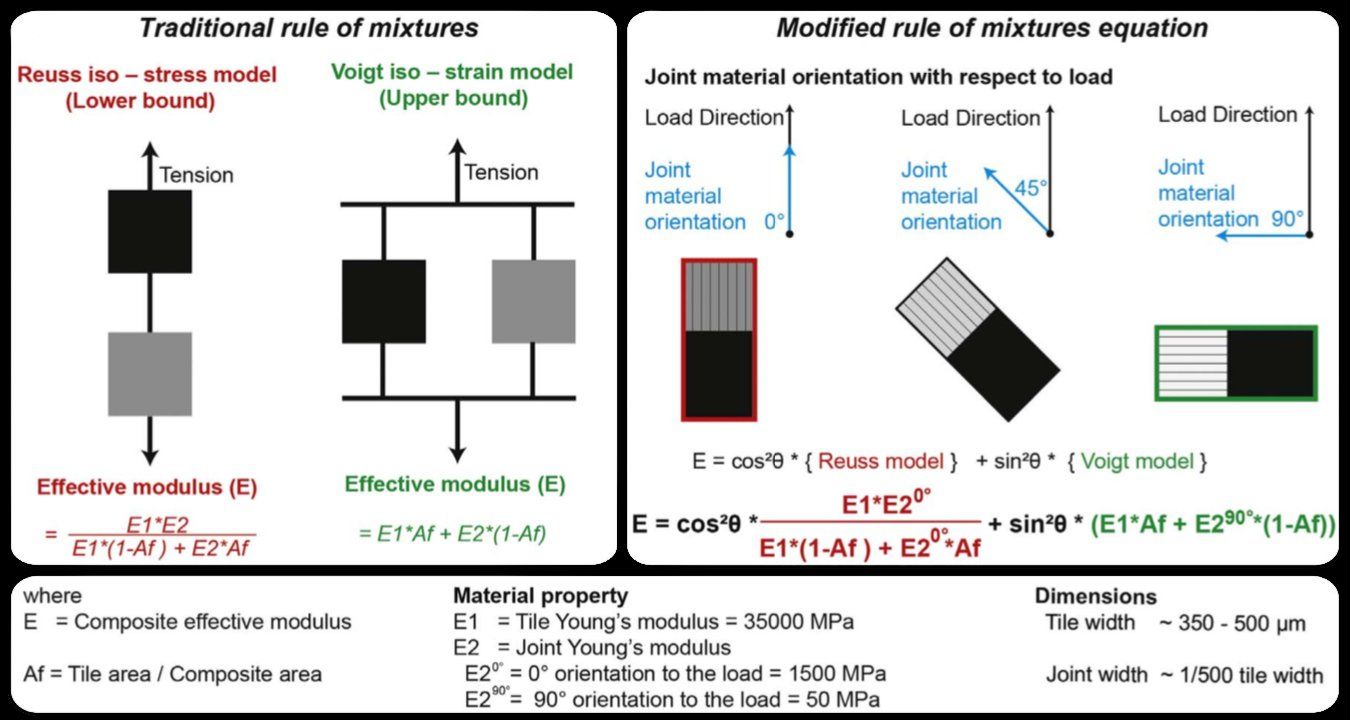

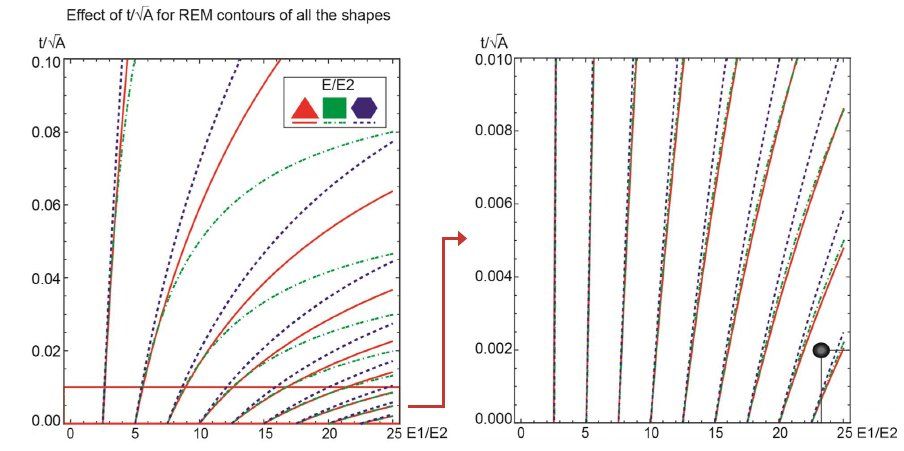

To calculate the effective modulus of modeled composites, we subdivided tiles and their surrounding joint material into simple shapes, for which mechanical properties (i.e. effective modulus) could be estimated using a modification of traditional Rule of Mixtures equations, that either assume uniform strain (Voigt) or uniform stress (Reuss) across a loaded composite material. For all examined tile shapes (triangle, square and hexagon) the composite stiffness increased as the width of the joints was decreased and/or the stiffness of the tiles was increased; this supports hypotheses that the narrow joints and high tile to joint stiffness ratio in shark and ray cartilage optimize composite tissue stiffness. Our models also indicate that, for simple, uniaxial loading, square tessellations are least sensitive and hexagon tessellations most sensitive to changes in model parameters, indicating that hexagon tessellations are the most “tunable” to specific mechanical properties.